limitation of hardness test|hardness testing load definition : factories In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different indenter types, such as diamond cones and carbide balls. Dagli autoclavi e i relativi accessori ai serbatoi zincati, dai serbatoi in polietilene ai vasi a membrana; all'interno di questa categoria trovate tutto quanto il necessario per le vostre esigenze di stoccaggio acqua.

{plog:ftitle_list}

Even small changes can make a big difference. For this reason, we have decided to make all MELAG documents available as PDF files. Please use the following selection or search fields. Your required document cannot be found .Transformants may be selected for in liquid media (option A) or on bacterial plates (option B); the procedure outlined in option B is adapted from Wetterauer et al. (23) (see http://dictybase.org/techniques/transformation/transformant_selection_on_bacteria.html and . See more

Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary to have properly prepared the surface of the .

how to use a refractometer when brewing beer

In this article, we briefly explained the importance and application, advantages . Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary to have properly prepared the surface of the sample to .In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different indenter types, such as diamond cones and carbide balls.

what is hardness testing

I. Why is the Vickers Hardness Test Significant? II. What are the Applications of Vickers Hardness Test? III. What are the Advantages of Vickers Method? IV. What are the Disadvantages of the Vickers Method? Conclusion. Introduction.Hardness of grinding wheels is measured by this testing method. Electromagnetic testing: Hardness is measured as a variable against. standards of known flux density. Ultrasonic testing: A type of indentation test. In the following chapters, most of these methods are covered.

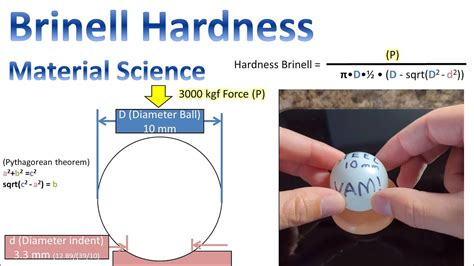

Understanding Hardness Testing: A Complete Guide | MachineMFG. Ever wondered why diamonds are so hard? In this article, we’ll explore the fascinating world of material hardness, from talc to diamond. You’ll learn how different tests, like Brinell, Rockwell, and Vickers, measure this crucial property, and why it matters in engineering.Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers.This article reviews the factors that have a significant effect on the selection and interpretation of results of different hardness tests, namely, Brinell, Rockwell, Vickers, and Knoop tests. The factors concerned include hardness level (and scale limitations), specimen thickness, size and shape of the workpiece, specimen surface flatness and .Hardness test procedures of various types have been in use for many decades. They are usually quick and easy to carry out, the equipment required is relatively simple and cheap, and there are portable machines that allow in situ measurements to be made on components in service.

static hardness testing

hardness testing standards explained

Learn about considerations, sample sizes, sample thickness, scales and hardness testing methods in this article about the hardness testing basics.

Each measurement shall not deviate by more than ±1% of the nominal test force for Brinell hardness (ISO 6506-1 2014), and each force measurement in the Vickers hardness shall not exceed the tolerance limit given in Table 1 (ISO 6506-2 2014).

Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary to have properly prepared the surface of the sample to .

In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different indenter types, such as diamond cones and carbide balls.I. Why is the Vickers Hardness Test Significant? II. What are the Applications of Vickers Hardness Test? III. What are the Advantages of Vickers Method? IV. What are the Disadvantages of the Vickers Method? Conclusion. Introduction.Hardness of grinding wheels is measured by this testing method. Electromagnetic testing: Hardness is measured as a variable against. standards of known flux density. Ultrasonic testing: A type of indentation test. In the following chapters, most of these methods are covered. Understanding Hardness Testing: A Complete Guide | MachineMFG. Ever wondered why diamonds are so hard? In this article, we’ll explore the fascinating world of material hardness, from talc to diamond. You’ll learn how different tests, like Brinell, Rockwell, and Vickers, measure this crucial property, and why it matters in engineering.

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers.This article reviews the factors that have a significant effect on the selection and interpretation of results of different hardness tests, namely, Brinell, Rockwell, Vickers, and Knoop tests. The factors concerned include hardness level (and scale limitations), specimen thickness, size and shape of the workpiece, specimen surface flatness and .

Hardness test procedures of various types have been in use for many decades. They are usually quick and easy to carry out, the equipment required is relatively simple and cheap, and there are portable machines that allow in situ measurements to be made on components in service.Learn about considerations, sample sizes, sample thickness, scales and hardness testing methods in this article about the hardness testing basics.

hardness testing scale

hardness testing process

An autoclave is a machine that uses pressured steam for a predetermined amount of time to sanitize materials and equipment. It is utilized in industrial, medicinal, and laboratory environments where it kills bacteria and spores by .

limitation of hardness test|hardness testing load definition